Investing in child rights is investing in supply chain resilience and security of supply. A well-managed supply chain, combined with sufficient training on child labour prevention, reduces the risk of child labour and improves workforce conditions. This leads to stable sourcing environments for brands, contributing to long-term, uninterrupted production even during external shocks.

This is what happened in 2022, when MADE in Myanmar discovered workers suspected to be under the age of 16, working full-time in a supplier’s factory in Myanmar.* In response, the brand notified the Fair Wear Foundation within 24 hours about the cases, which introduced The Centre to three brands sourcing from the factory. This then led to a two-year remediation programme for the factory supplying these brands.

In reponse to the notification, The Centre conducted an on-site assessment and confirmed five cases of child labour, along with four young workers engaged in work hours that exceeded the ILO’s requirements. A subsequent self-assessment carried out by the supplier with MADE’s support revealed 11 cases of child labour and 35 young workers aged 16 – 17. This issue largely stems from the tendency of young workers to present fraudulent identification documents or to use the documents of others when seeking employment.

Recognising the urgency of the situation, the brands and the factory agreed to support a remediation programme proposed by The Centre, focusing not just on immediate fixes but also on long-term solutions through funding and training. This was the most important step throughout the whole process, as fostering respect for child rights throughout the supply chain requires strong leadership and commitment at every level. This was not possible without the mutual trust established between the brands and the supplier. More often than not, brands would issue stop orders to supplying factories suspected of employing child labour. In contrast, this case stands out as an example of effective collaboration and good practice, the brands and supplier worked with an accredited third-party organisation to provide meaningful remediation for the affected children. The remediation programme also went beyond addressing existing child labour cases and incorporated a variety of training initiatives and established improved processes for the welfare of young workers, including supporting workers to obtain ID cards.

“Having The Centre as an independent and professional organisation as a remediation partner made the whole process for all involved parties much easier. Additionally – at least as a member brand of Fair Wear – it has been and continues to be immensely helpful to know that The Centre was so close to the young people and their families to ensure everything is in their best interest. We would have never been able to achieve this on our own.” An involved brand

Although child labour cases were reported, the supplier showed a strong commitment and willingness to collaborate. They welcomed suggestions for improving their recruitment strategies and actively worked to strengthen their systems to prevent child labour in the future. They are also a better employer due to their commitment and increased awareness of child labour prevention.

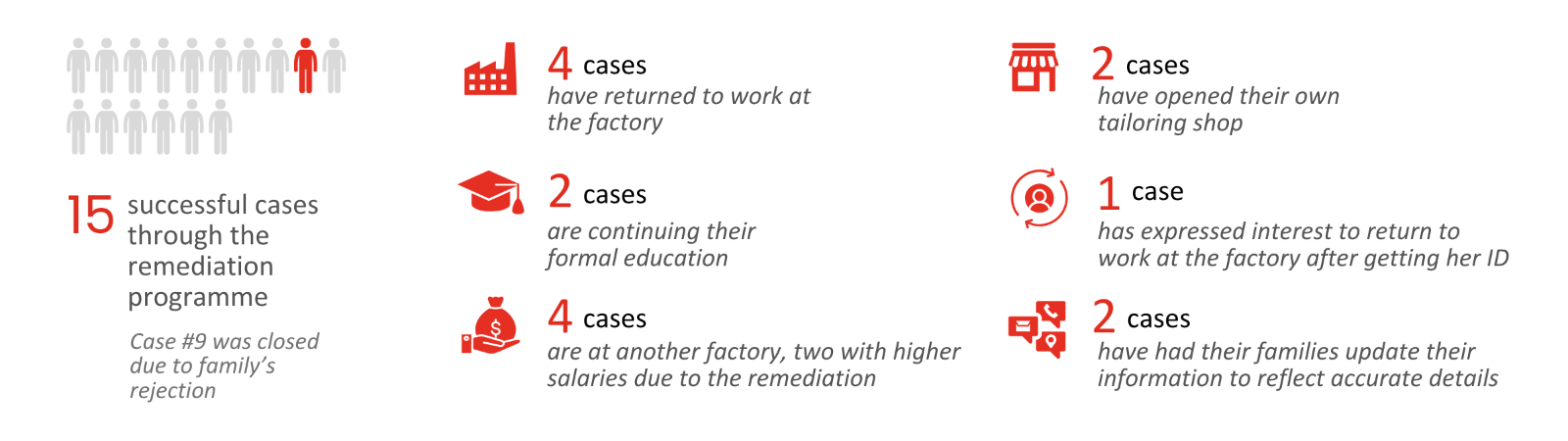

For two years, The Centre monitored all 16 child labour cases, ensuring compliance with individual educational remediation plans and disbursing monthly stipends and tuition support from a fund of almost USD 80,000 set aside by the factory and the brands. By March 2025, 15** cases had been successfully supported and completed the remediation programme.

Remediation Outcomes by March 2025:

After responsibly recruiting and managing the training of young workers through The Centre’s and MADE’s support, the factory has continued to implement its young worker management programme as part of its long-term sustainable development initiatives. This programme aims to:

Offer full-time job opportunities to young workers over the age of 16

Provide decent working conditions for young workers

Conduct regular awareness-raising activities for frontline supervisors and middle management to enhance their capabilities in managing young workers

Monitor practices to ensure they align with relevant policies and procedures, particularly regarding age verification, medical checks, and working conditions for young workers

Offer on-site training focused on young workers’ professional and personal development to build a stable and efficient team of young workers

Provide mentoring and peer support to improve the lives and job satisfaction of factory workers

“My English skills have improved, and it has been a great opportunity for me to learn all four aspects of the language. Her mother also expressed satisfaction, saying, "My daughter has enhanced her English skills, particularly in grammar. She often states that she is happy to have learned English skills, which will really benefit her future career.” Remediation programme participant, who is continuing her formal education (Age: 18 years, 4 months)

“My dream is to learn sewing, and through this programme, I can fulfil that dream. Now I have acquired many skills related to sewing, and I am confident that I can open my own sewing shop in the future”.” Remediation programme participant, who currently runs her own tailoring shop (Age: 16 years, 6 months)

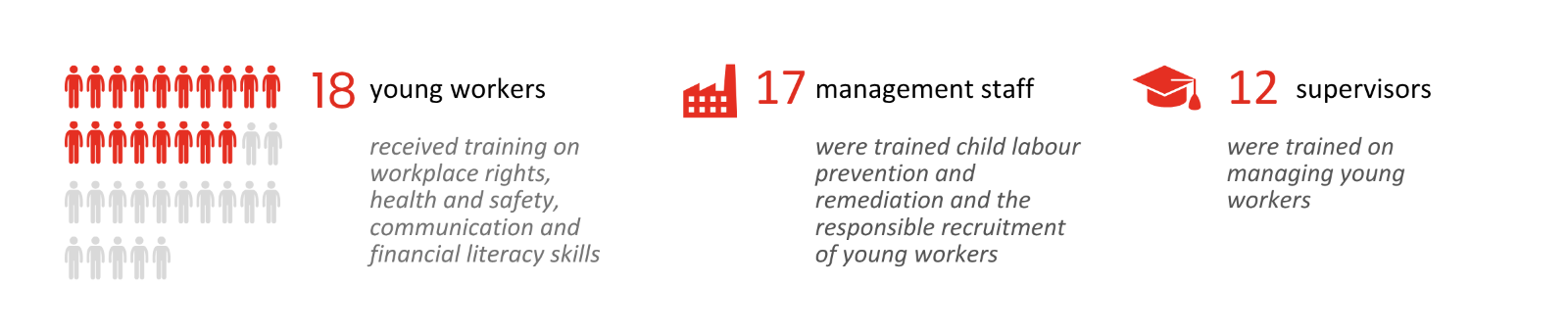

Young Worker Management Outcomes:

“Thank you to The Centre’s team for doing such a great job mentoring us all through this challenge to protect the young people of Myanmar and find good programmes to develop their skills, setting them on the right path, with the community supporting them through caring guides at hand. We’re very proud to have worked with you all to achieve these fantastic results.” One of the brands

* In Myanmar, the legal working age is set at 14 years old for non-hazardous positions, with a restriction of working only four hours a day. However, this standard does not align with the requirements of the International Labour Organization (ILO). As a result, we adhere to the more stringent standard provided by the ILO, which means that this practice is classified as child labour.

**One case was closed as unsuccessful because the family rejected assistance after only one month of remediation support. Their child stayed home and immediately rejoined the factory upon turning 16.

2025/12/16

Webinar: Addressing Child Labour in Complex Upstream Supply Chains: Agriculture, Mining and TextilesBy using this website, you agree to our use of cookies. We use cookies to provide you with a great experience and to help our website run effectively.